OUR PRODUCTS

Automated Gas Permeameter/Porosimeter (POROPERM)

The automated Gas Permeameter is used to measure both the permeability and porosity of core plugs. Permeability is determined with either steady state or unsteady state method and the equivalent liquid permeability and slip factor are calculated. Porosity is determined with isothermal gas expansion and application of Boyle’s law. The unit is equipped with a custom-made high-speed data acquisition system, gas regulator, digital display, solenoid valves, pressure transducers, laptop with installed software, Hassler type core holder, pump, etc. Software has different modules for visualizing the process, data entry, showing the pressure and temperature and status of the valves, results and summary, graphs, calibration configuration, and generating reports. Absolute permeability, porosity, grain density, pore volume, slippage factor, and air permeability are presented at the end of the test.

⮞ Features

▪ Confining Pressure: Up to 10,000 psi (customizable) – Manual and automated systems are available

▪ Operating Temperature: Ambient

▪ Measurement Type: 3 options available

– Fall off (unsteady state)

– Pulse decay (unsteady state)

– Steady state

▪ Permeability Range: 10nD-10D (depending on the measurement type)

▪ Porosity Range: Up to 60%

▪ Gas Type: Customizable (N2, He, Air)

▪ Core Diameter: Customizable (Standard: 1 and 1.5 inches)

▪ Core Length: Customizable (Standard: 0 to 4 inches)

▪ Pressure Accuracy: 0.1% FS

▪ Electrical Requirement: 110-220V, 50/60 HZ

▪ Dimensions: 20inch × 26inch × 16inch

▪ Accessories: O-rings, rubber sleeve, toolbox, calibration plugs, instruction manual, etc.

▪ Warranty: One year from installation

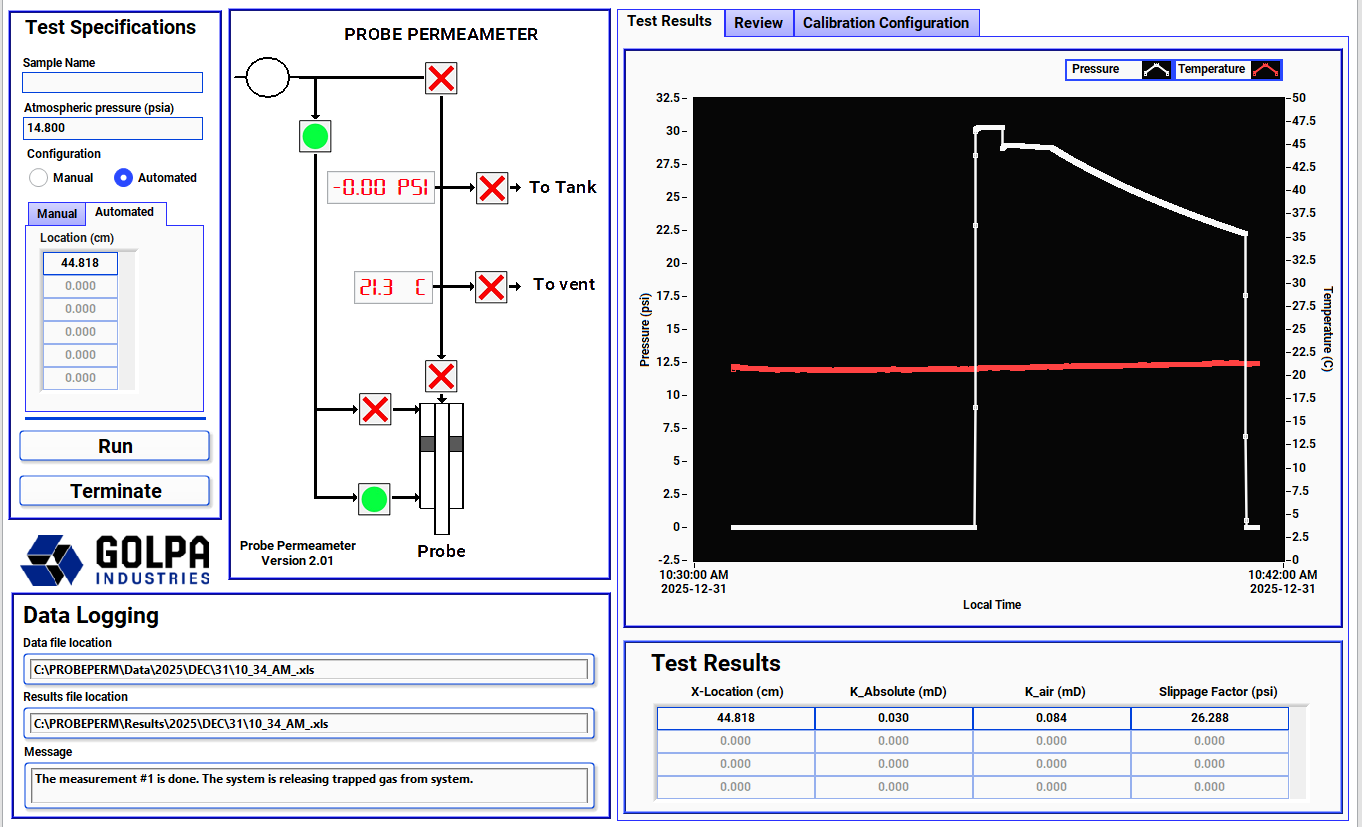

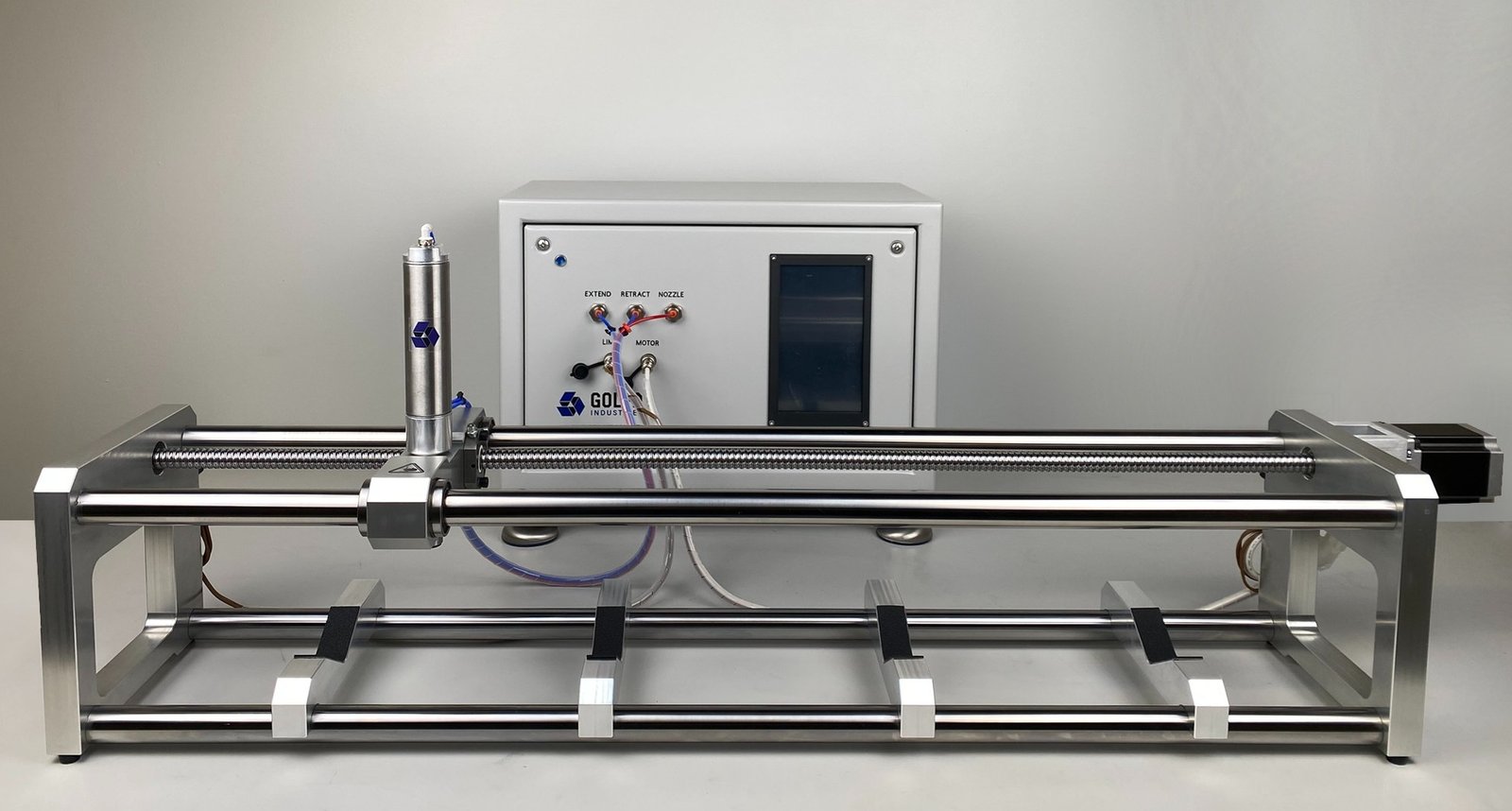

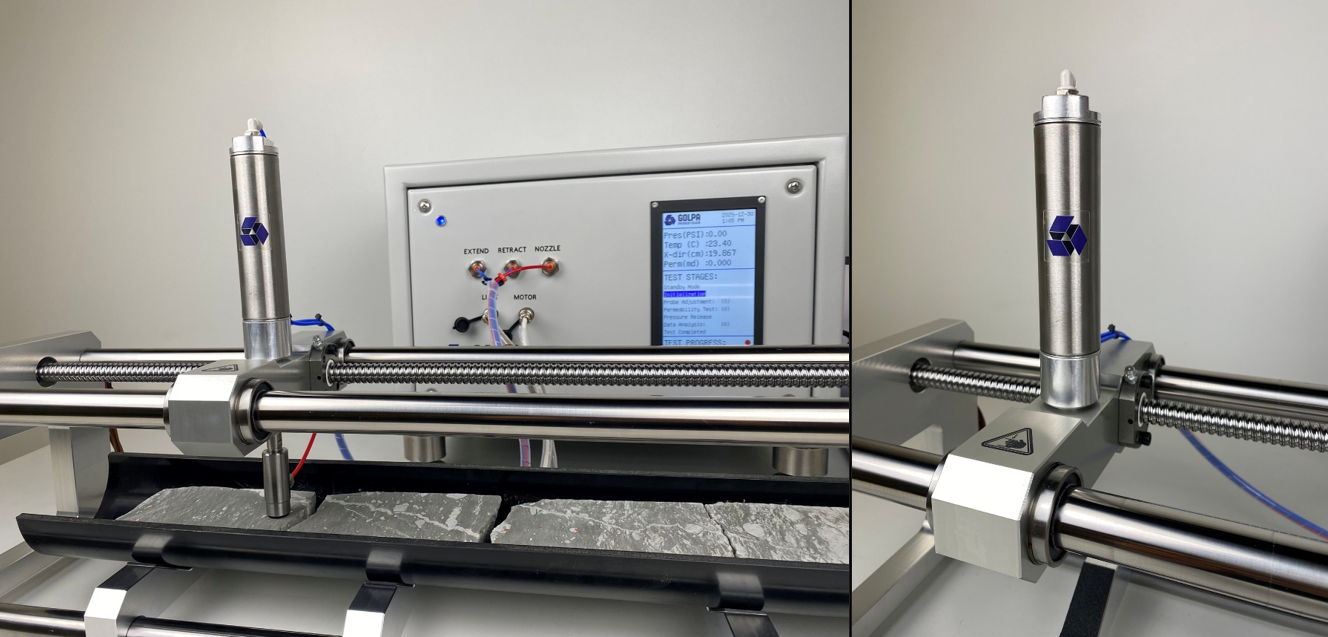

Probe Permeameter (PROBE-PERM)

Probe permeameter instrument is used to perform fast, non-destructive, and localized permeability measurements on slabbed core samples (without confining pressure) using unsteady-state approach. Probe permeameter provides spatial permeability measurements in samples where routine analysis cannot capture the degree of core heterogeneity or core shape. A measurement is taken by positioning the probe tip along the x-direction at a desired location on the sample. Then a pneumatic actuator lowers the probe to the sample surface, and Nitrogen/air is injected through the probe tip. Permeability is calculated by measuring the rate of pressure decay with an accurate pressure transducer and taking into account the complicated geometry of gas flow in the sample around the injection probe. The system integrates pressure and temperature sensors, control components, and dedicated software to regulate test conditions and acquire measurement data. The software is developed in a user-friendly environment and includes modules for test setup, real-time visualization of test parameters, probe positioning and adjustment, data entry, calibration configuration, graphical analysis, results and summary, and automated report generation.

⮞ Features

▪ Permeability Measurement Type: Unsteady State

▪ Permeability Range: 0.01mD-10D

▪ Gas Type: Air/Nitrogen

▪ Operating Temperature: Ambient

▪ Maximum Gas Inlet Pressure: 120 psi

▪ Probe Injection Pressure: 30 psi

▪ Max Core Height: up to 4 inches (Customizable)

▪ Probe Movement Length: 33 inches (Customizable)

▪ Probe Tip Outer Diameter: 15 mm (Customizable)

▪ Pressure Accuracy: 0.1% FS

▪ Electrical Requirement: 110-220V, 50/60 HZ

▪ Warranty: One year from installation

Data Acquisition System (GI–8AI2AO13RL)

A data acquisition system (DAS) is a device that records the physical conditions such as pressure and temperature and converts them into digital data and controls other devices such as valves, regulators, flow controllers, etc. This data can then be stored and analysed by a computer. The data acquisition system developed by GOLPA Industries is a compact and versatile device that could be used in your workstations/labs to control and monitor the processes/experiments. The developed software is user-friendly, customizable and has different modules for data entry, showing the parameter values (pressure, temperature, etc.), status of the valves, graphs, and calibration configuration.

⮞ Features

▪ Input: 24V DC 10A(max)

▪ Connection Type: Micro USB 2.0

▪ Max Sampling Rate: 20 kS/s

▪ Analog Input Resolution: 14 bits

▪ Analog Input Absolute Accuracy: 26 mV

▪ Dimensions: 16cm × 17.4cm × 8.9cm

▪ 8 Analog Input Channels (Pressure, temperature, flow meter, etc.); Working voltage: -10 to +10 V

▪ 2 Analog Output Channels (Regulator, control valves, flow controllers, etc.); Working voltage: -10 to +10 V

▪ 13 Solid State Relays Channels (for switching valves) 0.5A max

▪ Accessories: USB cable, software, protective case, instruction manual, terminal blocks, power supply

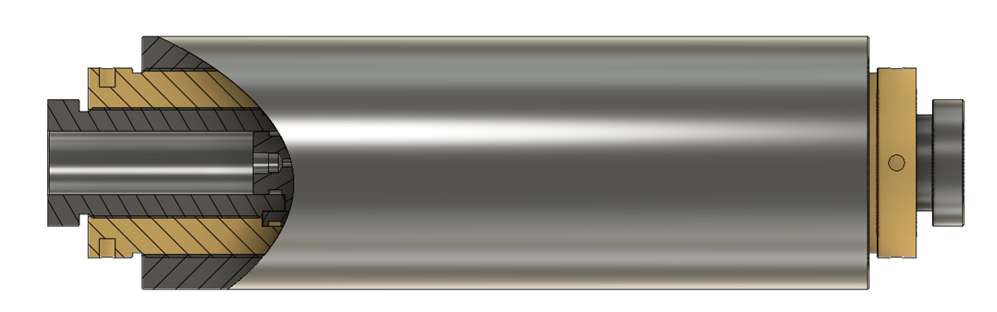

Hassler Type Core Holder (HCH series)

Core holders are used to hold a core sample for porosity, permeability or other core flooding tests. This design allows for fast loading and unloading the core plugs without completely disassembling the core holder or draining the confining fluid. After releasing the confining pressure and unscrewing the end plugs, the core sample is easily removed from the sleeve while the sleeve and end caps are remained in place in the core holder. This design is recommended for shorter core plugs and single core diameter applications. Spacer(s) are provided to accommodate shorter core plugs. A groove pattern is utilized on the distributor plugs to evenly distribute the fluid flow on the whole face of the core sample before entering and exiting the core sample.

⮞ Features

▪ Core Diameter: Customizable (Standard: 1.5 inches)

▪ Core Length: Customizable (Standard: 0 to 4 inches)

▪ Confining Pressure: Up to 10,000 psi

▪ Operating Temperature: Up to 150 °C

▪ Fitting: NPT (2 confining pressure ports, 1 inlet port and 1 outlet port)

▪ Wetted Part Material: Stainless steel

▪ Sleeve/Sealing Material: Nitrile, Viton

▪ Confining Pressure Type: Radial pressure (axial pressure is optional)

Note: Stand is optional

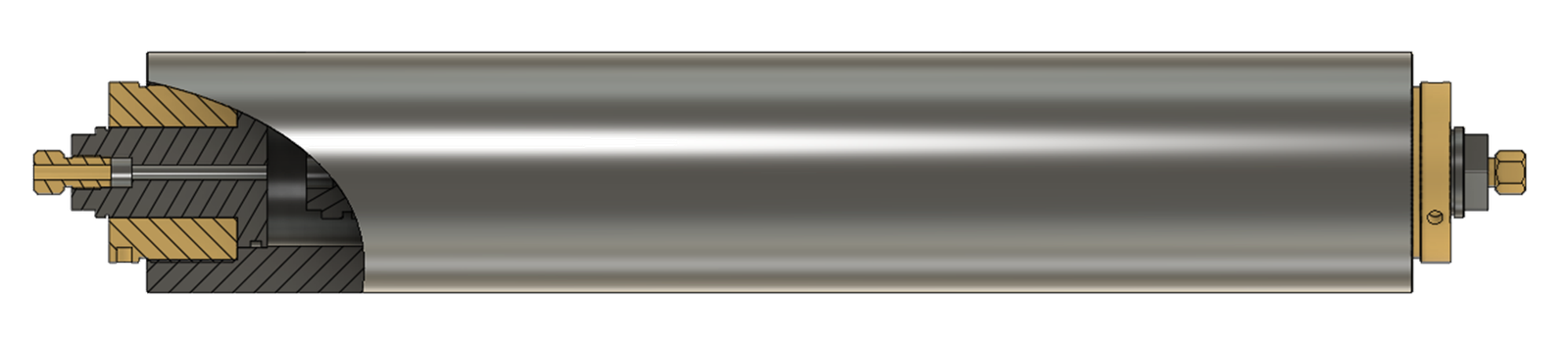

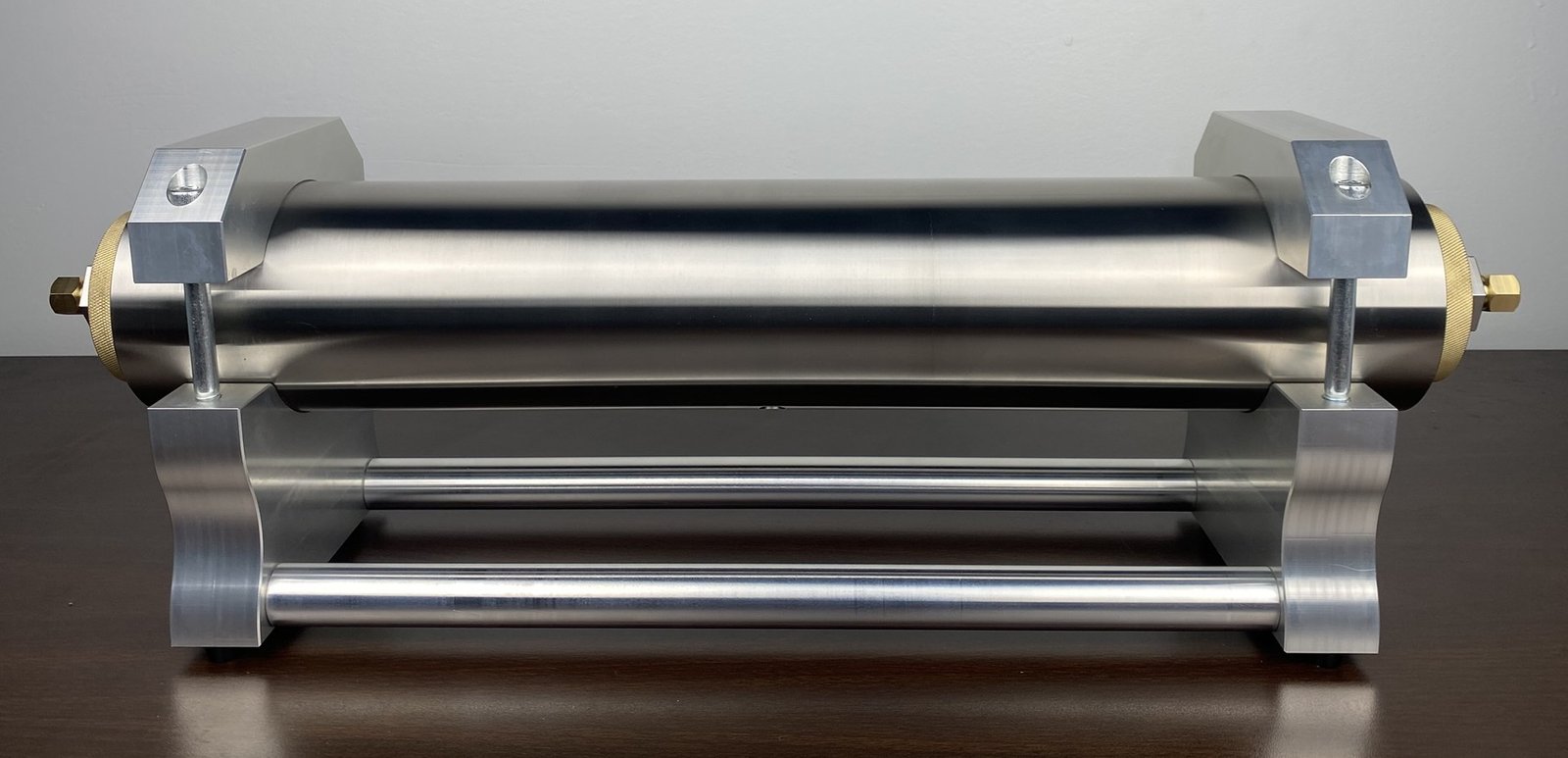

Standard Core Holder (SCH Series)

Core holders are used to hold a core sample for porosity, permeability or other core flooding tests. In this style, multiple core plug diameters can be tested in the same core holder with minimal part replacement. Core length is adjusted by moving the floating distributor plugs inside the core holder. This design is recommended for longer core plugs and unconsolidated core samples. A groove pattern is utilized on the distributor plugs to evenly distribute the fluid flow on the whole face of the core sample before entering and exiting the core sample.

⮞ Features

▪ Core Diameter: Customizable (Standard: 1.5 inches)

▪ Core Length: Customizable (Standard: 0 to 12 inches)

▪ Confining Pressure: Up to 10,000 psi

▪ Operating Temperature: Up to 150 °C

▪ Fitting: NPT (2 confining pressure ports, 1 inlet port and 1 outlet port)

▪ Wetted Part Material: Stainless steel

▪ Sleeve/Sealing Material: Nitrile, Viton

▪ Confining Pressure Type: Radial pressure (axial pressure is optional)

Note: Stand is optional

Floating Piston Accumulator (FPA series)

Floating Piston Accumulators (Transfer cylinders) are used in oil and gas/chemical industries to store and displace liquid and gases for laboratory experiments.

⮞ Features

▪ Internal Volume: Customizable (Standard: 500 cc)

▪ Operating Pressure: Up to 5,000 psi

▪ Operating Temperature: Up to 150 °C

▪ Fitting: NPT

▪ Material: Stainless steel/Aluminum/PEEK

▪ Sealing Material: Nitrile, Viton

Note: Stand is optional

Calibration Plug Set

Precision calibration plugs for porosity/volume calibrations in a protective case

⮞ Features

▪ Outside Diameter: Customizable (Standard: 1.5 inches)

▪ Inside Diameter: Customizable (Standard: 0.5 – 1 inches)

▪ Length: Customizable (Standard: 3 inches)

▪ Material: Stainless steel, Aluminum